Motor Technology News

March / April 2011

Turbocharger production gets a boost

Continuing the theme of what has become a popular series of features looking back at some of the more interesting and exciting projects we've been involved with during our 25 years, in this issue of Motor Technology News we're looking back to 2002 when turbocharger manufacturer, Garrett Engine Boosting Systems, asked us to look at automating the turntable jigs used to set the required inlet and outlet port angles, so that each one would fit perfectly with the engine it was being made for. The company manufactures and remanufactures over 300 different types of turbochargers, destined for manufacturers such as, Scania, Volvo and Peugeot/Citroen, plus the independent aftermarket in Europe, The Middle East and Africa.

As part of the final assembly process the port angles had to be set to an accuracy of within 0.2 degrees so that they aligned correctly with the matching ports on the engine. Previously this was accomplished manually on a rotating turntable jig, with the correct angles being read from a mechanical scale marked around the edge. Whilst the system worked satisfactorily, it was time consuming and vulnerable to human error as operators had to read from a long list of 10-digit part numbers to establish the correct port-angle settings for each product. Misreading from the list would obviously result in the port angles being set incorrectly.

The solution was developed after working in close consultation with Garrett’s own engineers. We designed and installed an automated system that enabled the jig operators to select the relevant 10-digit part number on an easy-to-use control panel. Software, written by Motor Technology, drives the system and powers a database containing the part numbers and specifications of all Garrett’s turbochargers. After selecting the relevant part number on the controller, the two port angles, named Epsilon and Alpha, are shown clearly on two digital displays. Each one shows the actual and required port-angle settings so that the operator can position the turntable until both of them match.

Read more here

Economy drives

Not all applications need high-end drive controllers with features like simultaneous position measurement systems, super high resolution, clock synchronism for up to 256 axes and accuracy to the microsecond, which are some of the fantastic features of today’s high performance drive controllers.

These features represent progress for the demanding applications that need them, but there are many others where reducing costs, without loosing current levels of performance and functionality, is more important. In these instances LTi’s range of CDE drives is the perfect solution. Despite being up to 40% lower in cost, than an equivalent high-end drive, the CDE range offers fantastic performance and functionality.

Read more here

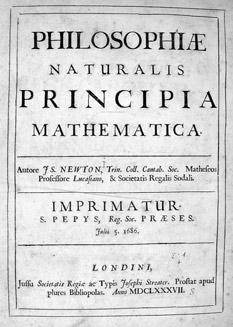

Newton's laws of motion and the

difference between mass and weight

Newtons laws of motion come in pretty handy for engineers engaged in the business of moving things, and in this issue of Motor Technology News we're going to take a look at them and get back to first principles by getting to grips with the difference between mass and weight.

Newton described three laws of motion that form the basis of classical mechanics. The first states that every object remains in a state of rest or constant velocity unless acted upon by a force.

The second law states that a mass (m) acted upon by a force (F) will undergo acceleration (a) in the same direction as the force with a magnitude that is directly proportional to the force and inversely proportional to mass. Therefore F = ma.

The third law states that the forces of action and reaction are equal and opposite. When a body exerts a force (F) on another body, it in turn exerts a force (-F) on the actor. F and -F are equal in magnitude but opposite in direction.

And this is why a good understanding of the difference between mass and weight is essential for engineers doing calculations about moving stuff. Imagine if we were on a space ship in weightless orbit. Now imagine that one of your colleagues throws you a spanner. When you catch it you apply a force sufficient to decelerate it, but once it has stopped accelerating it will feel weightless, and that's because of the absence of another force – gravity.